It is fabric-reinforced on a base and can be made in various heights. It is fabric-reinforced on a base and can be made in various heights.

Crowned Pulleys Which Option Is Right For You Sparks Belting

But also describes web behavior at misaligned rollers guides and winders.

. Therefore an 18 face width pulley 4. These flat belts stayed centered on pulleys without any guides or flanges. Such arrangements are used when wide spans or high moment loads need to be supported.

The crossed-roller bearing design is the roller equivalent of the x-type ball bearing design. The accuracy and efficiency of a machine toll are determined by the stiffness and friction torque of roller guide. As implied these rollers are machined at each end of a solid core.

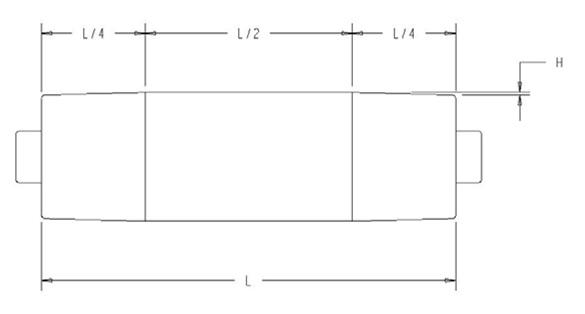

A crowned pulley eliminates the need for pulley flanges and. A crowned roller is a drive drum with a cylindrical center section with 2 tapered sections on each end. For pivotable carrying rollers.

A press-fit design requires the machining of end caps and the tube then press-fitting the end caps into the tube. A crowned roller is a drive drum with a cylindrical center section with a tapered section on each end. This study proposes an improved design method for roller guide.

If you need this in bulk we have it available. Roller from product debris. The conveyor belts arc of contact on the drive drums is to be increased.

If you need this in bulk we have it available. _____ KEYWORDS Web Spreading Mechanics Roller Bowed Spreader Roller Concave Roller D-Bar. Linear Bearings Guides Guide Wheels.

A crowned pulley is a pulley that has a slight hump in the middle tapering off ever so slightly towards either edge. Roll crowning is intended to ensure proper web alignment and helps minimize the effects of deflection. Conveyor design can aide greatly in minimizing the issues associated with belt tracking.

When the flat belt on such a pulley is off-center and the pulley rotating the belt quickly moves up to the largest radius at the top of the crown and stays there. Genetic algorithms are also used in other kind of study. 157 to 189 inch.

Slotted mounts are suitable for less heavily loaded rollers eg. The key to keeping them tracking centered on the pulleys is the use of crowned pulleys. The Roller Company provides a range of precision machined industrial roller crowning and grinding services to ensure you get the most out of your precision machined industrial rollers.

0313 in Stud Length 0625 in Thread Size 516-18 Thread Length In 045 in Thread Length mm - Step Size In. If the arc of contact of snub rollers sup - port and guide rollers is small the dia-meters of these rollers may equal 12 d. Similarly the web will also tend to exit a.

Also covered are spreader design considerations and troubleshooting techniques. In a crossed-roller bearing the races are conical surfaces at angles of 45 to the axis of rotation. The tracking measure will also work for reversing operation.

Crowned Races in contradistinction to conical races would function with less scuffing in rollerrace contact areas. A convex crowned pulley usually has an increase of - 116 per foot of pulley width. On pulleys with 24 face width some engineers prefer a convex crown pulley shape.

Guide rollers are preferable to lateral wear strips in this respect. We make corrugated sidewalls. As a general rule only as many pulleys and rollers should be installed as are necessary to carry and guide the belt.

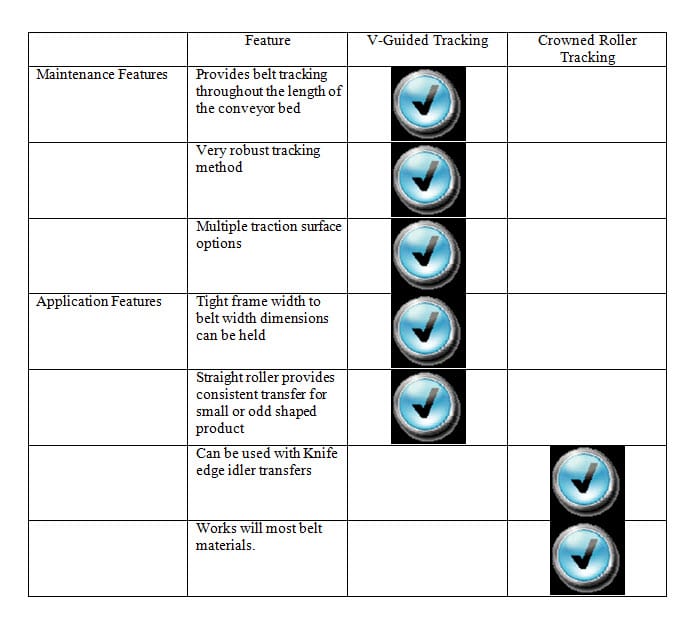

Designed to run on flat surfaces or in C channel track the uses are limited only by your imagination. The 2 most common methods used to aide in the belt tracking are crowned roller and v-guided belting. Crowned rollers have a slight curve which is invisible to the naked eye to stay centered on surfaces that are not perfectly aligned andor not perfectly flat.

In this unique process a rotating tube is heated using direct heat. 138 in Roller Width 038 in Stud Type Concentric Stud Dia. The 2 most common methods used to aid in the belt tracking are crowned roller and V -guided belting.

The distance between the top and return side must be small for design or construction reasons. Corrugated sidewalls splicing accessories. Conveyor design can aid greatly in minimizing the issues associated with belt tracking.

Corrugated sidewalls splicing accessories. Each pulley and roller can be the cause for belt running problems as well as for accumulation of debris. Including styles such as Cylindrical Convex Crown Straight Taper with Center Flat Straight Taper Concave Crown and more.

Rollers expander rollers D-bars and more. Snub rollers are used when. The shape of a crown is nominally the shape of a beam deflected under a uniformly distributed load as shown in Figure 3.

Crowned rollers have resulted in greater load-carrying capability and longer bearing lifeCrowned rollers under load distribute stress equally along their full length of contact with the raceways thereby eliminating stress concentration at the roller ends. Crowned pulley tracking is a pulley with a cylindrical middle section and tapered ends. Design a better roller using these 2 innovative techniques.

The crown is important to keep the belt tracking stable preventing the belt from walking off the edge of the pulley. We make corrugated sidewalls. 440C stainless steel rollers offer better corrosion resistance than chrome-plated steel rollers.

Others prefer a straight taper with center flat. For technical drawings and 3-D models click on a part number. Even on troughed conveyors flat face and crowned pulleys are generally used.

MadeWell Crown Rollers can be used in conjunction with DualVee Guide Wheels for applications requiring pairs of linear guide systems operating in parallel. 138 to 1417 inch. Typically the smallest diameter pulley a V-guide belt can go over is a 1 diameter pulley.

How a crowned pulley keeps the belt tracking on it is a mystery. 05313 to 409 inch. The influences of the rollers profile on stiffness stress distribution of roller linear guide are analyzed using finite element simulation.

This method of tracking works by using the tapered ends of the pulley to steer the belt back to the center of the roller when it starts drifting off to the left or. For example in the design of spherical parallel manipulators 25 in the design of crowned cylindrical roller bearings 13 estimation in. The latest computerized grinding machines along with the basic beam principle roller specifications and the users operating load requirements are the factors leading to precision crowned rollers.

Up to 4 cash back Cam Follower Roller Style Stud Face Design Plain Roller Shape Crowned Roller Dia. Edge guide strips are best suited for relatively clean conveying operations as debris may become lodged between the belt and guide strip causing significant belt damage and other performance problems.

Belt Conveyor Tracking V Guided Vs Crowned Roller Dorner Conveyors

The Basic Theory Of Crowning Industrial Rollers Pdf Free Download

Belt Conveyor Tracking V Guided Vs Crowned Roller Dorner Conveyors

Roller Design For Conveyor Belts Elasticbelt

Crowning Benefits Paper Film Foil Converter

Crowning Data For Conveyor Belt Rollers Splawn Belting

0 comments

Post a Comment